Rules

Only words with 2 or more characters are accepted

Max 200 chars total

Space is used to split words, "" can be used to search for a whole string (not indexed search then)

AND, OR and NOT are prefix words, overruling the default operator

+/|/- equals AND, OR and NOT as operators.

All search words are converted to lowercase.

Infrastructure programme

The University Centre for Electron Microscopy – UCEM, was established as the first infrastructural Research Centre at the University of Maribor by a Decision of the University Senate on 1 August, 2005. It was established with the aim of combining knowledge and experience on Electron Microscopy and for the highest quality research work, and maximising the use of the large amount of research equipment, which was combined for this purpose. The basic goal of UCEM is to enable the greatest possible access to research equipment for all teachers, students and researchers at the University of Maribor, other research institutions, as well as the Economic sector in the eastern region of Slovenia. The planning of research work is related to the acquired research projects and programmes, where we introduce new ways and methods of research.

Within the UCEM are two microscopes – an HRSEM Sirion with microchemical EDS analyser and ESEM Quanta 3D.

- The Sirion 400 NC electron microscope is a high-resolution electron microscope with Field Electron emission, which enables extremely high magnifications (up to a million times, with a high resolution of 1 nm). A feature of this research equipment is its suitability for both engineering materials and biological samples.

- Quanta 3D is an environmental Scanning Electron Microscope with a tungsten cathode for an electron source (formation of an electron beam with heat emission). The microscope has the name "environmental" because it allows working at different pressures and at 100% humidity. Conditions for observing different samples are obtained by adjusting the pressure in the chamber. ESEM-mode microscopy is, thus, suitable not only for conductive materials such as metals and metal-coated materials, but also for moist, volatile, and soft materials without prior preparation, which is particularly important for the Food and Chemical industries.

Another special feature of this equipment is a focused ion beam FIB SEM (the ion gun on the SEM Quanta microscope), which allows not only SEM observation of the surface, but also surface treatment and analysis of the microstructure below the surface.

We perform procedures for optimal sample preparation for Electron Microscopy and examinations, along with examination and classification of nanoparticles of metal compounds. We also review and participate in the classification of “rare earth” compounds with cobalt, which are the basis for the fabrication of strong magnets.

For the last several years, we have been investigating and inspecting precious metal alloys used in jewellery, for dental prosthetics and industry regularly.

Admission of Slovenia to the European network of Euro-BioImaging infrastructure centres

The Slovenian Consortium of Infrastructure Centres (SiMBioN) dealing with biomedical and biochemical imaging, of which the University Centre for Electron Microscopy (UCEM) of the Faculty of Mechanical Engineering of the University of Maribor is also a member, was founded in 2018 under the coordination of the University of Ljubljana, Faculty of Medicine. The vision of this Consortium was to bring together groups using different imaging methods with the aim of an interdisciplinary approach to the analysis of biological and medical samples.

In order to work more successfully with infrastructure centres across Europe, the Consortium has launched an initiative to join the European network of Euro-BioImaging infrastructure centres. With the support of the Ministry of Education, Science and Sport, the decision to join was made by the Government of the Republic of Slovenia, who committed to the obligations of the Member States of Euro-BioImaging. The application for Slovenia's membership was considered by the Board of Directors of Euro-BioImaging, and at its session on 5 May, 2020, it accepted Slovenia as its full member.

Slovenia's inclusion in Euro-BioImaging enables its researchers to access state-of-the-art equipment in the European infrastructure centres, participate in European infrastructure projects and participate in planning a vision for the development of European infrastructure in the field of Biomedical Imaging methods.

Upon Slovenia's inclusion in the Euro-BioImaging organisation, an interview with the coordinator of the Slovenian consortium, Prof. Dr. Peter Veranič, is available on the web link:

https://www.eurobioimaging.eu/news/slovenia-joins-euro-bioimaging-eric-/.

Multicomponent composites with embedded gold nanoparticles

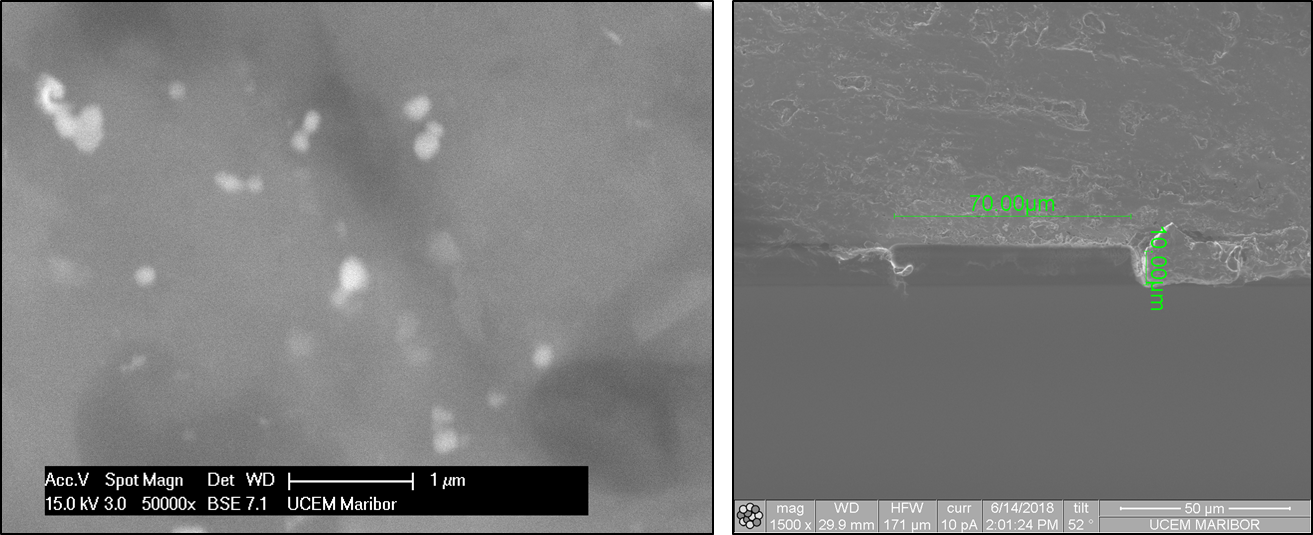

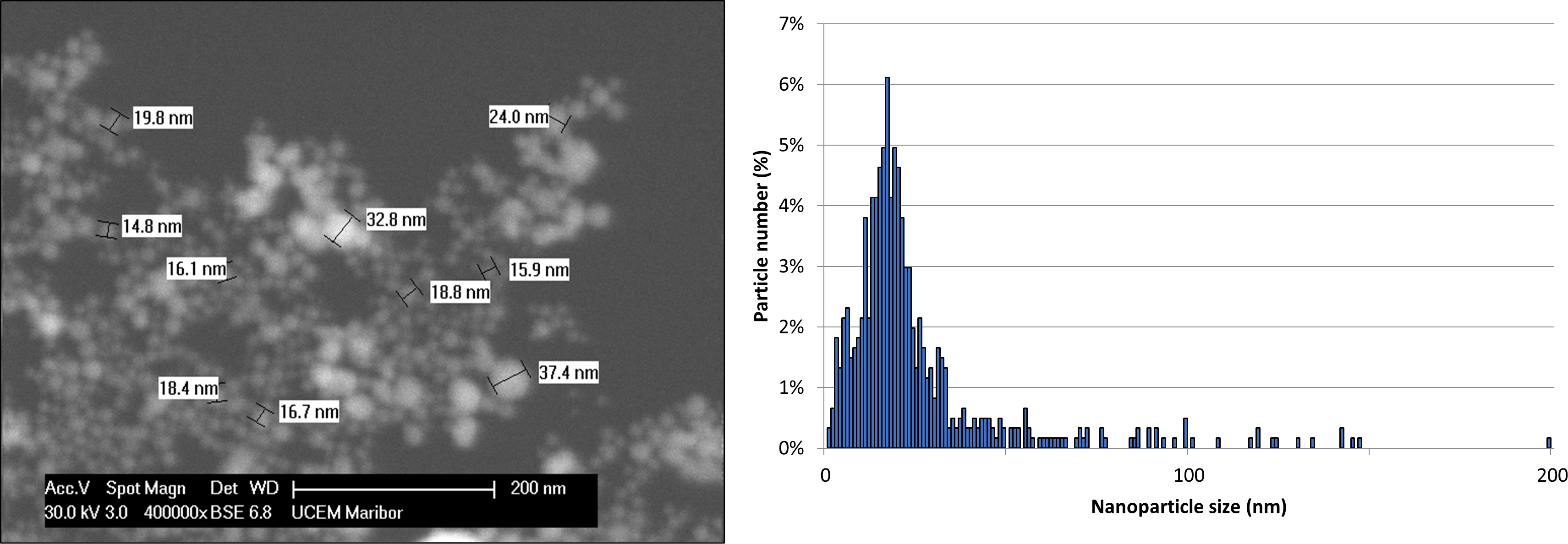

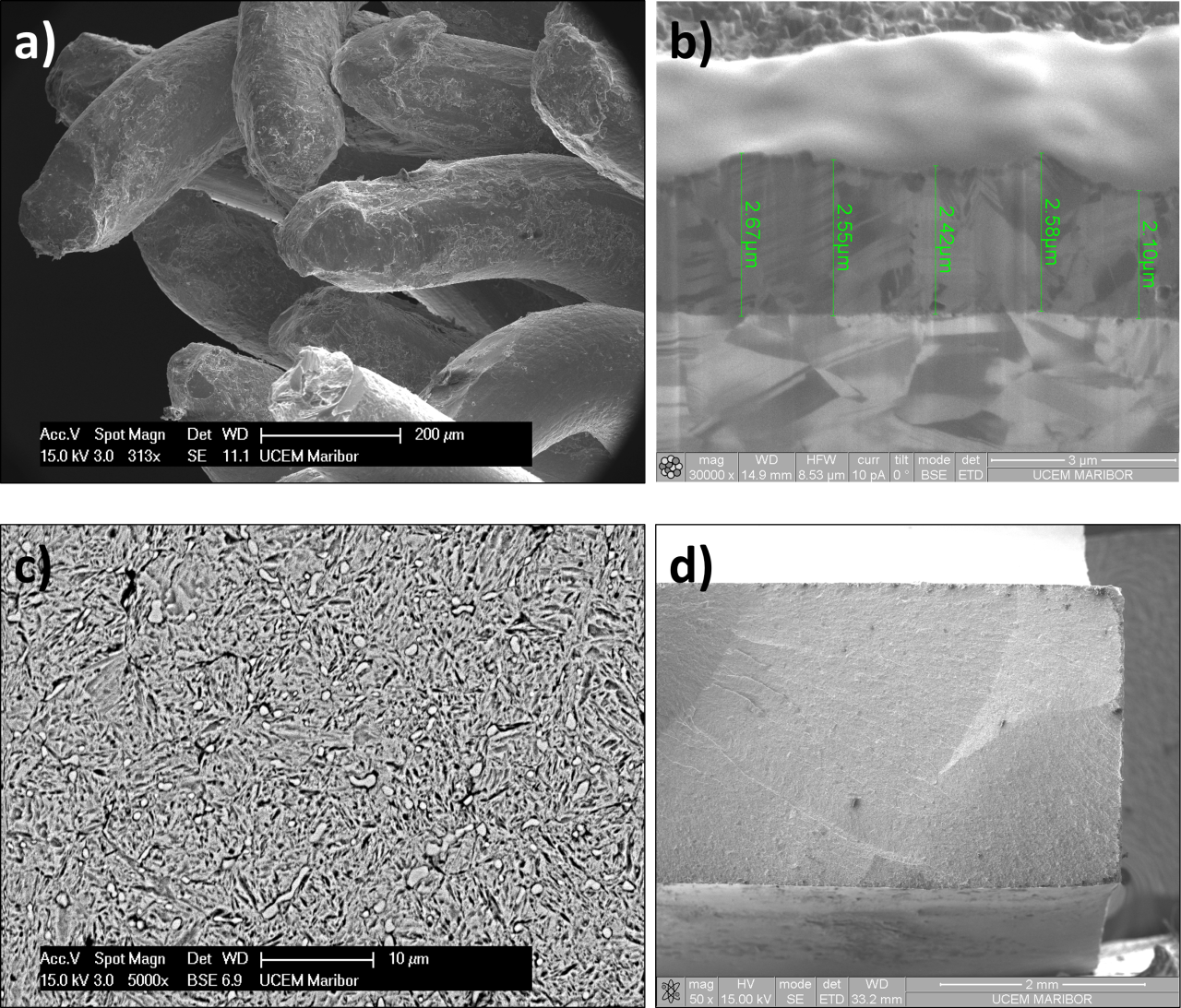

Using the Quanta SEM environmental Scanning Electron Microscope, we are investigating multicomponent composites (Eureka PRO-NANO Project-Zlatarna Celje d.o.o.) with embedded gold nanoparticles. In the research, we are observing gold nanoparticles and their distribution in the polymer matrix.

Figure 1: Demonstration of a multicomponent composite with embedded gold nanoparticles (the composite was prepared by classical thermal polymerisation, using acrylic acid with initiator-KPS for the monomer; gold nanoparticles were synthesised from an Au-chloride precursor).

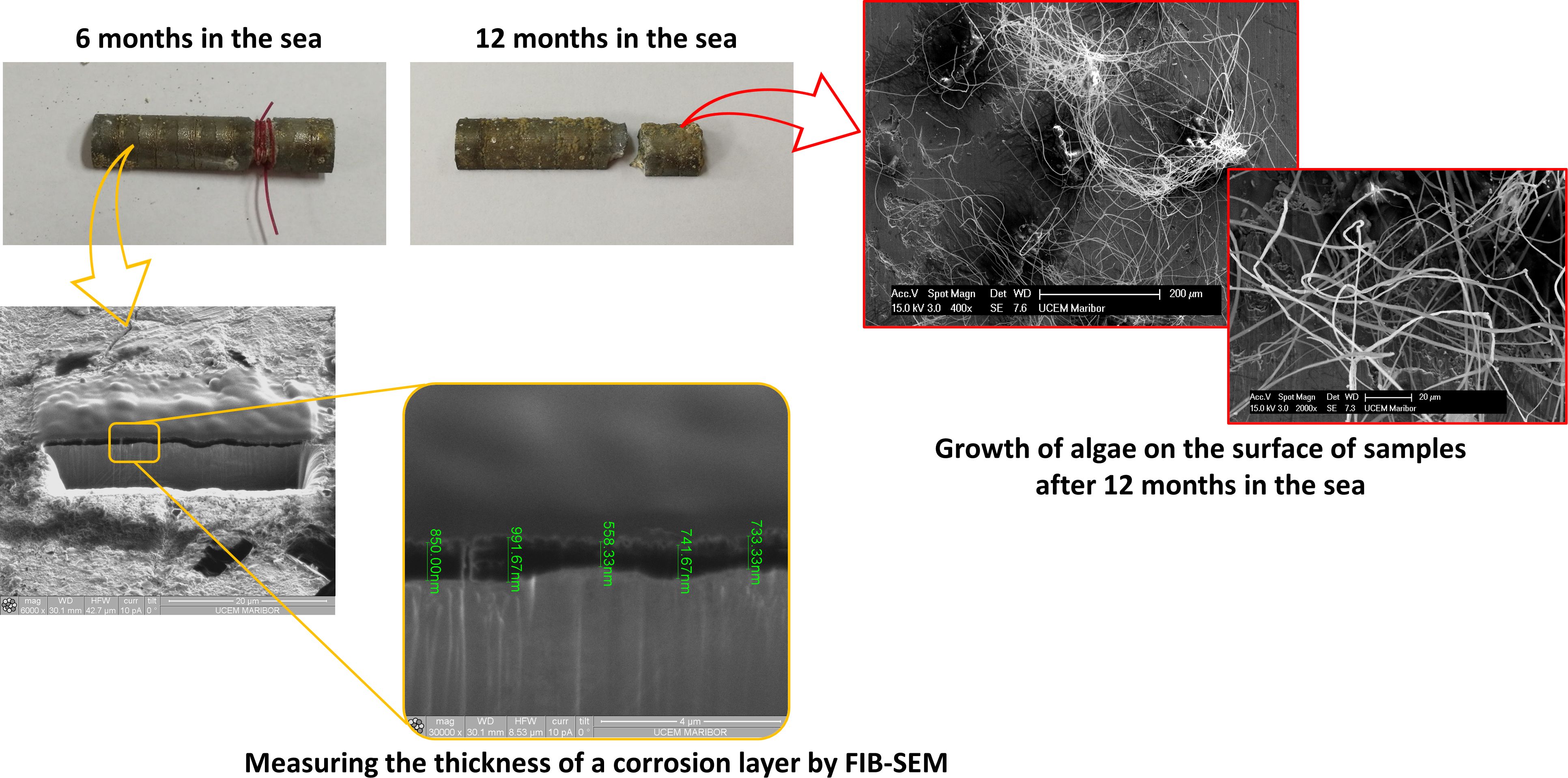

Testing the corrosion resistance of different materials for maritime use

In cooperation with the Faculty of Maritime Studies, Kotor, from the University of Montenegro, we have been, and will continue to investigate, the impact of seawater on the corrosion process in various metal samples from three locations: The seabed, sea level (tide), and at a distance of 3 m from the sea, depending on the duration of exposure: 6, 12, 18 and 24 months. An analysis of the corrosion process of the outer surface of the samples was performed at UCEM using a light microscope, SEM microscopy in combination with EDX analysis, and FIB cross-sections of the outer surfaces of the samples.

Figure 2: Demonstration of the investigation of samples after corrosion testing - the influence of sea water.

Figure 3: Measurement of pitting corrosion depth.

The SEM characterisation is continued with the analysis of samples exposed to the sea at different times of the year. We are studying the impact of 1- and several-months' exposure at sea on selected materials.

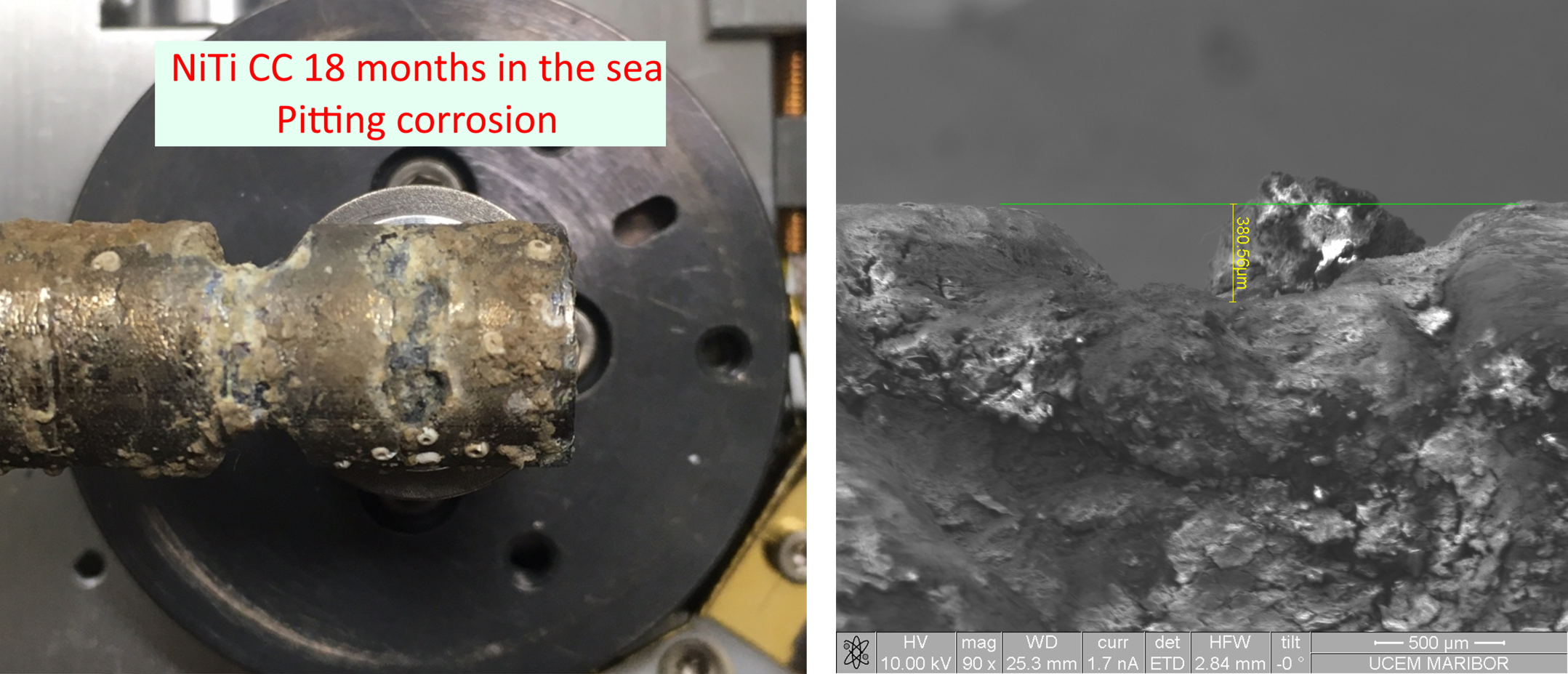

Development of nanostructured composites` production, Fe‐Au core‐shell, for various applications

In collaboration with the IME Institute for Recycling and Metallurgical Processes, RWTH, Aachen, Germany, we continued our research on nanomaterials` production with USP synthesis. For this purpose, we approached the synthesis of Fe-Au core-shell nanoparticles, or the development of the nanostructured composites` production. The characterisation of nanoparticles is crucial to determine their properties, and to obtain information on the necessary corrections of the USP synthesis parameters. The aim of the research was to determine the microstructure of nanoparticles, and to produce core-shell particles with a more continuous Au layer. We focused on the use of the STEM (Scanning Transmission Electron Microscopy) detector on the FEI Quanta 200 3D microscope, which enables the observation of characteristics at the nanometer level, and the SEM/FIB method for the characterisation of nanoparticles across their volume.

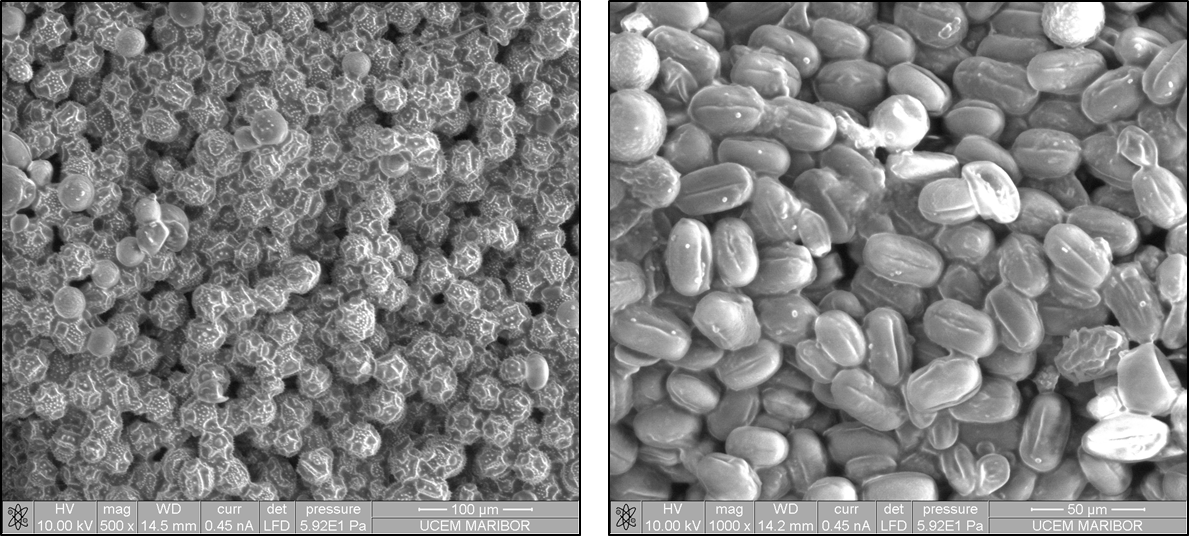

Figure 4: Development of the production of Fe particles covered with Au nanoparticles. Optimisation of the production parameters enabled the production of Fe particles with a more uniform covering of Au nanoparticles.

Development of a module for 3D printing of biologically complex structures for use in regenerative medicine

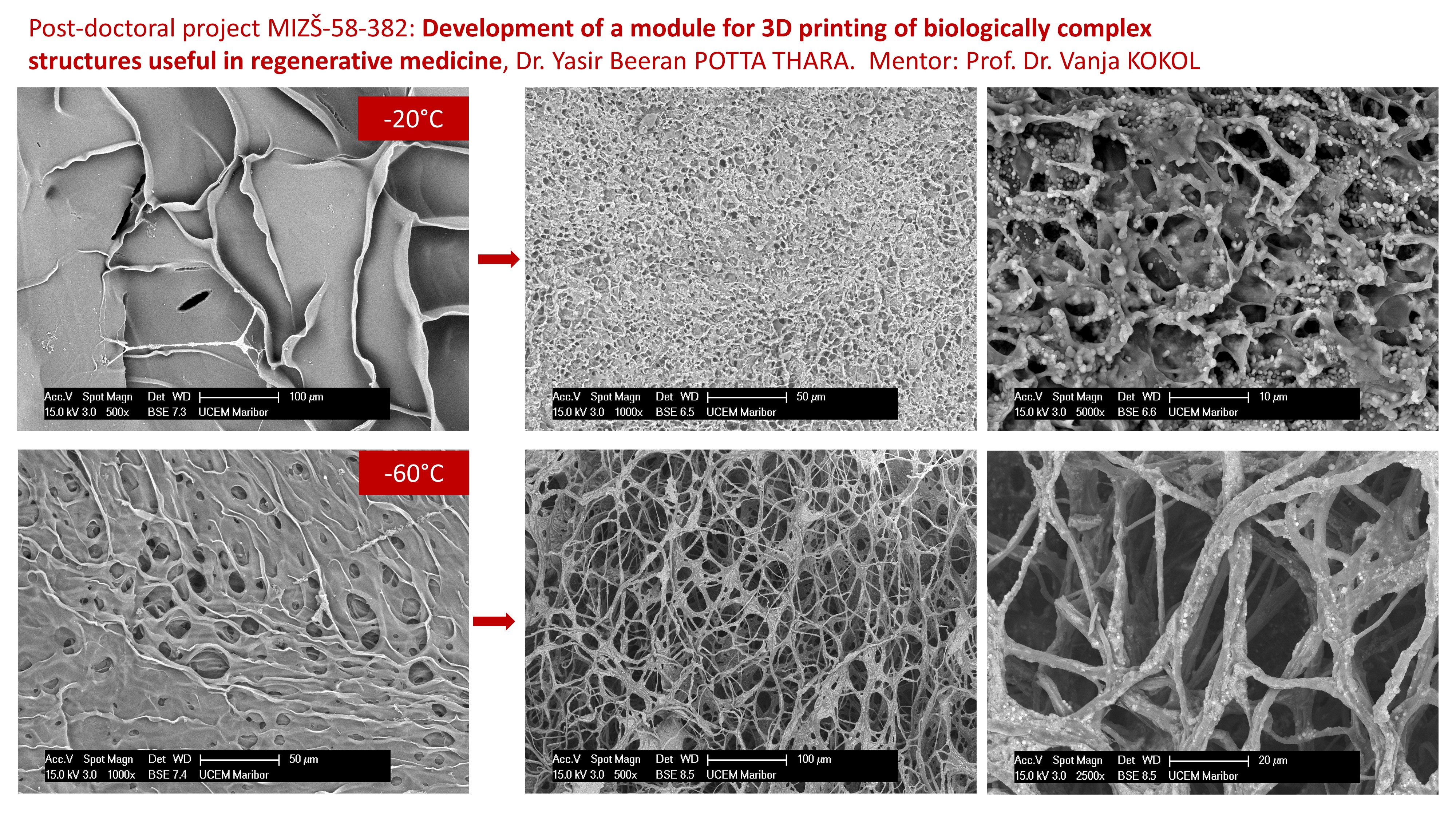

Post-doctoral project MIZŠ-58-382: Development of a module for 3D printing of biologically complex structures useful in regenerative medicine, Dr. Yasir Beeran POTTA THARA. Mentor: Prof. Dr. Vanja KOKOL

Figure 5: Modulation of the structure and degradation of a bioactive gelatine-collagen carrier enriched with nanohydroxyapatite - nanoHA: before (left) and after 7 days of incubation in in-vivo conditions (right).

Research support

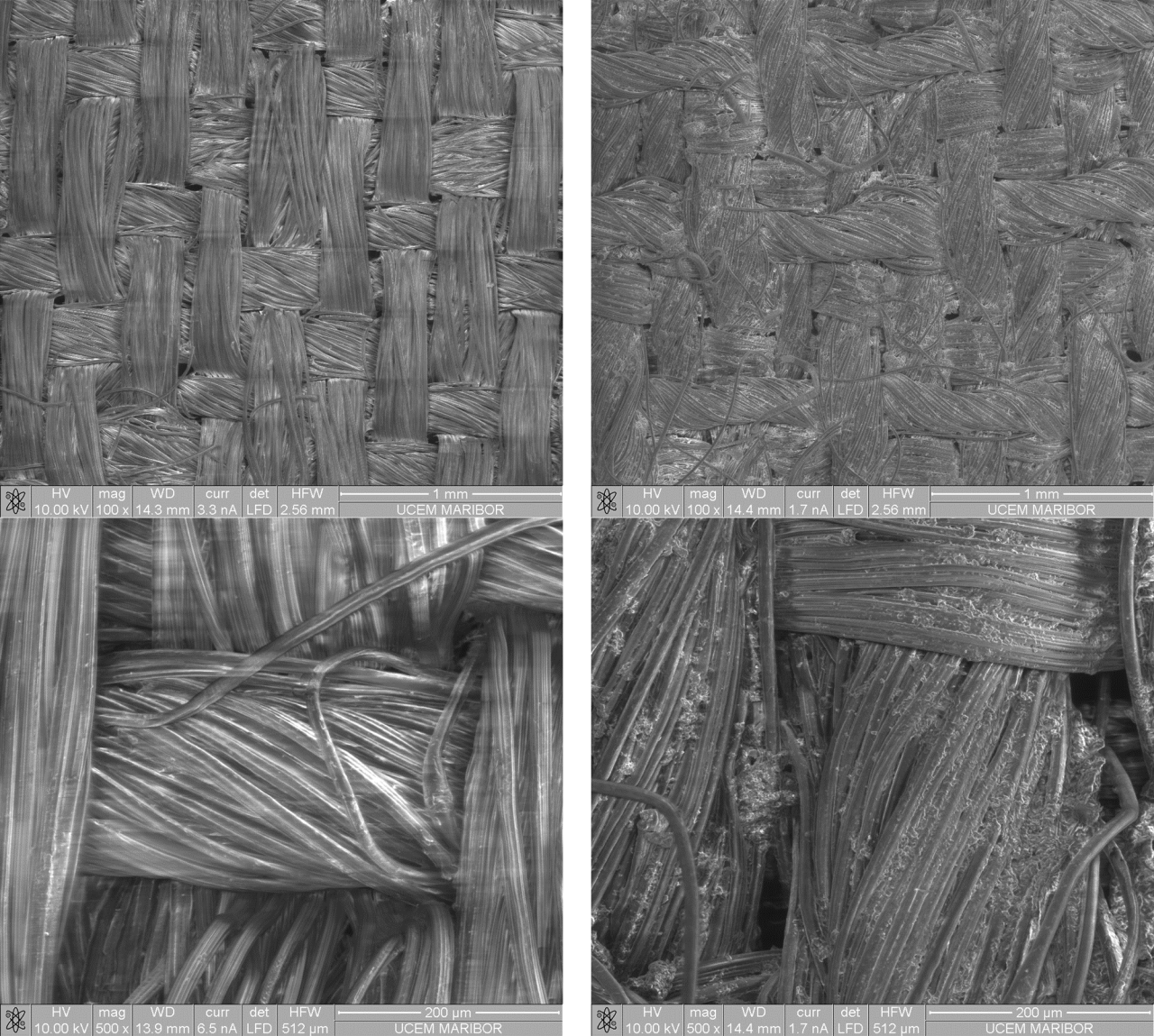

We are continuing giving infrastructural support to users, undergraduate and postgraduate students, researchers at UM, UL and other research organisations and companies, for their investigations in the field of Materials Engineering, as well as for examinations of biological and medical samples.

Figure 6: SEM characterisation of pollen.

Figure 9: a) SEM characterisation of fatigue fractures of Cu-electric conductors from household appliances; b) FIB measurements of the thickness of Ag/Au galvanic coating on various jewellery items for Zlatarna Celje; c and d) Analysis of the microstructure and fracture of the prototype tool steel for SIJ Ravne Systems' knives.

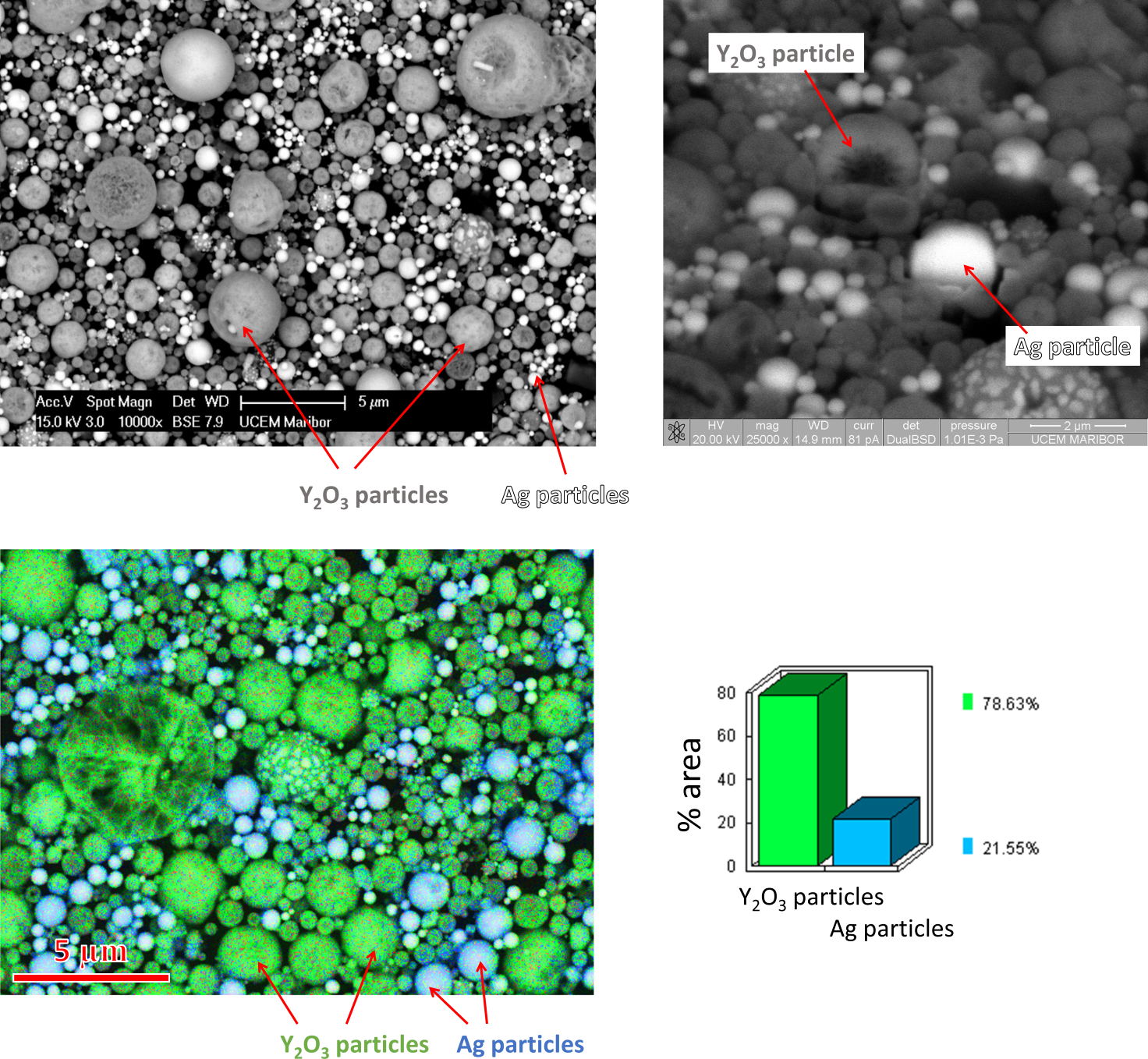

Y2O3:Eu/Ag micro- and nanoparticles designed for various applications using their exceptional photoluminescence

In collaboration with the IME Institute, RWTH Aachen Germany, we performed the characterisation (size, shape and chemical composition) of photoluminescent particles from oxides of rare earth metals, Y2O3:Eu, which are intended for different types of applications. The particles were made by the USP process.

Figure 10: SEM/EDX and SEM/FIB characterization of Y2O3:Eu/Ag micro- and nanoparticles intended for different applications using their photoluminescence.

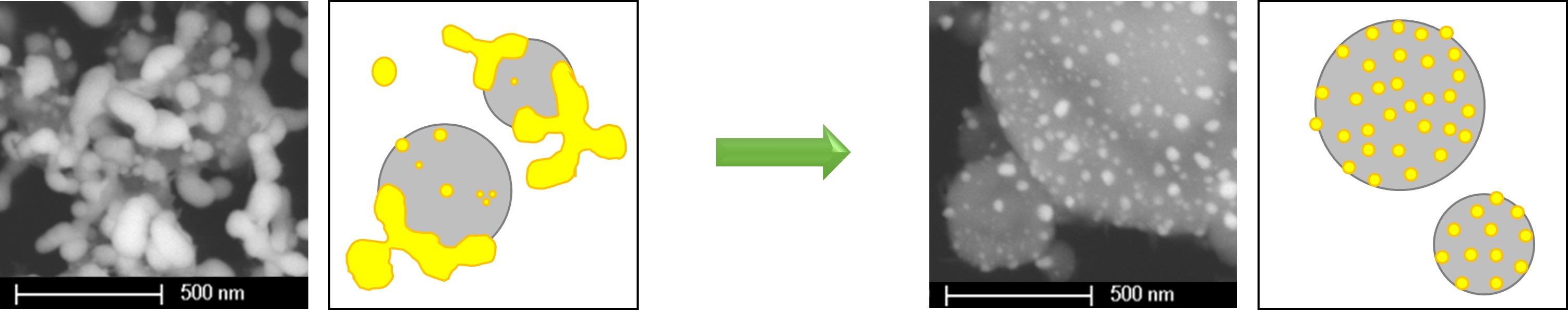

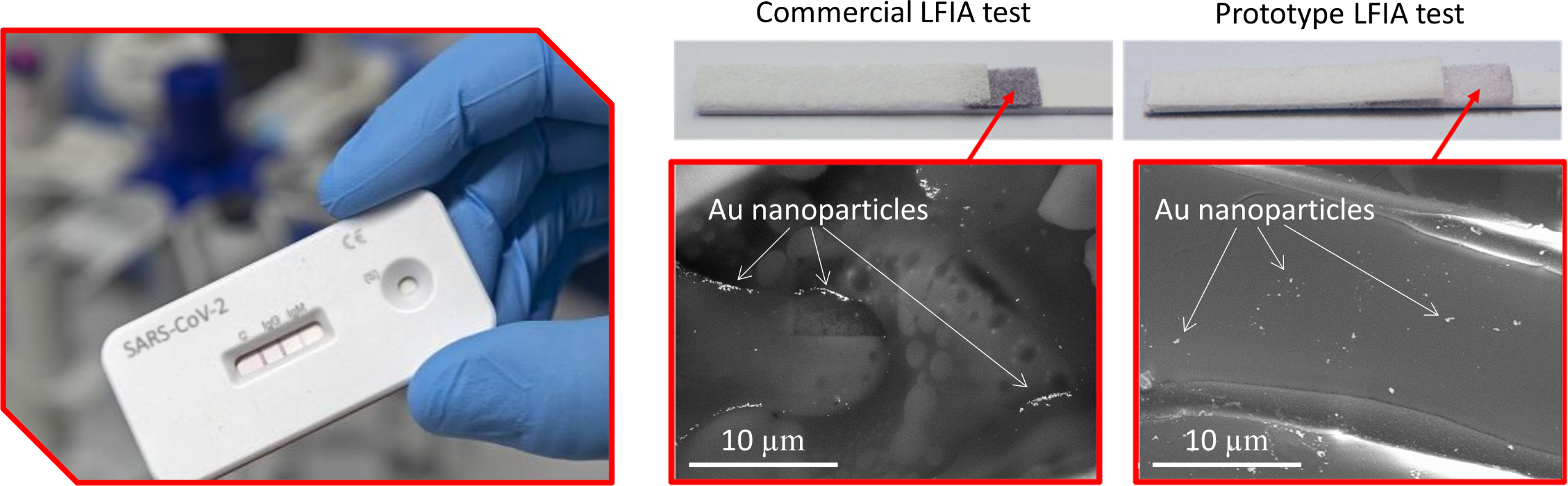

Rapid antigen LFIA test to detect Covid-19 infection based on gold nanoparticles

The acquired knowledge in the field of USP synthesis and the ability to produce Au nanoparticles with target morphology, unimodal size distribution and specific surface properties were the basis for the development of a rapid serological test (LFIA) for the detection of SARS-CoV-2 virus antibodies. In the development of the test, Au nanoparticles represent one of the basic components of the test - a label for the detection of antibodies in blood samples of test subjects potentially infected with the SARS-CoV-2 virus. The research and development work of the new prototype LFIA test continues with clinical testing at the University Medical Centre Maribor.

Figure 11: Demonstration of a rapid antigene LFIA test prototype and comparison of Au nanoparticle distribution on the conjugate pad of a competitive and prototype LFIA test.